Containerboard

At three locations in Germany, Progroup produces high-quality containerboard exclusively on the basis of recovered paper. The three high-performance plants ensure that Progroup's eleven corrugated sheetfeeder plants receive a continuous supply of raw materials. With its “K-Line” and “SLW-Line” product lines, Progroup offers a wide range of paper grades. .

Progroup supplies a wide range of different paper varieties with grammages of from 60 to 230g/m2. The special technology of the PM2 paper machine makes it possible to produce light, fibre-saving papers from the Next FibreⓇ brand for “Next Generation” corrugated board that is lighter and powerful at the same time.

Created for many assignments. Programmed for strong performance.

The requirements placed on kraft papers today extend in two directions: specialist papers for specific applications and less fibre use while retaining consistent strength properties. Progroup is able to meet both demands with the K-line. Depending on where the packaging is going to be used, priority is given to different strength criteria for the papers and corrugated board – such as penetration resistance and stackability. Progroup uses four steps to adapt the papers to suit the relevant performance requirements.

The “green” basis for a corrugated board generation.

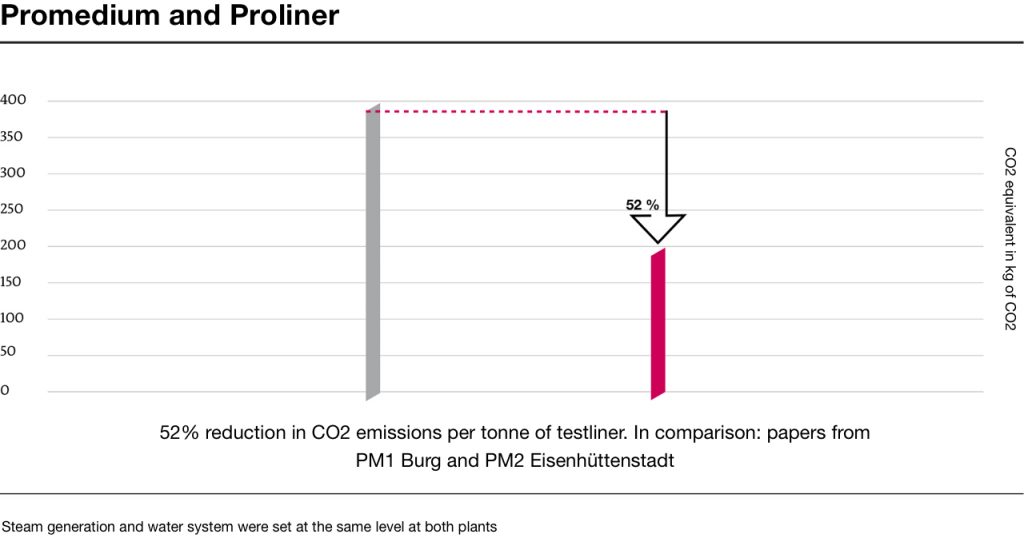

Recovered paper is the most important raw material used in the manufacture of containerboard today. Global demand is rising – the supply is becoming scarcer and the price will continue to fluctuate at a high level. To ensure that corrugated board also remains competitive as a product in the future, Progroup Paper has with the SLW-line developed containerboard that saves resources and is strong at the same time.

The brands Proliner for test liner papers and kraft liner substitutes from 80 to 230 g/m2 and Promedium for corrugated board papers from 60 to 180 g/m2 meet the most demanding requirements. New and pioneering additions to our range are the Next FibreⓇ papers – economically produced high-performance papers with a low grammage, made from 100% recovered paper in a way that conserves resources. All papers pass through a consistent quality assurance process, and reliable brand quality is guaranteed. Ask us about technical details.

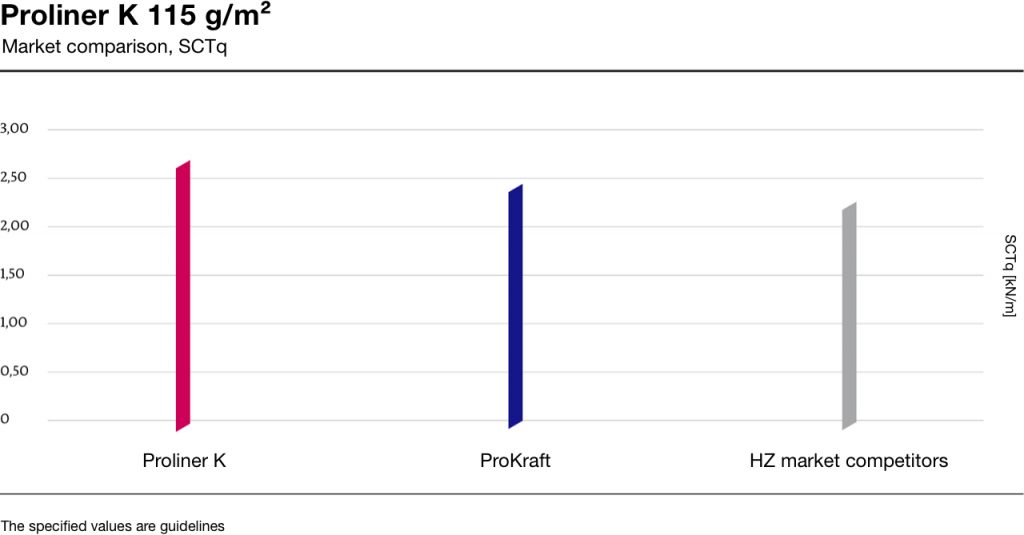

The high-quality kraftliner substitute for the highest SCT values.

Use

Grammage

Wet strength

Cobb 60

Approval

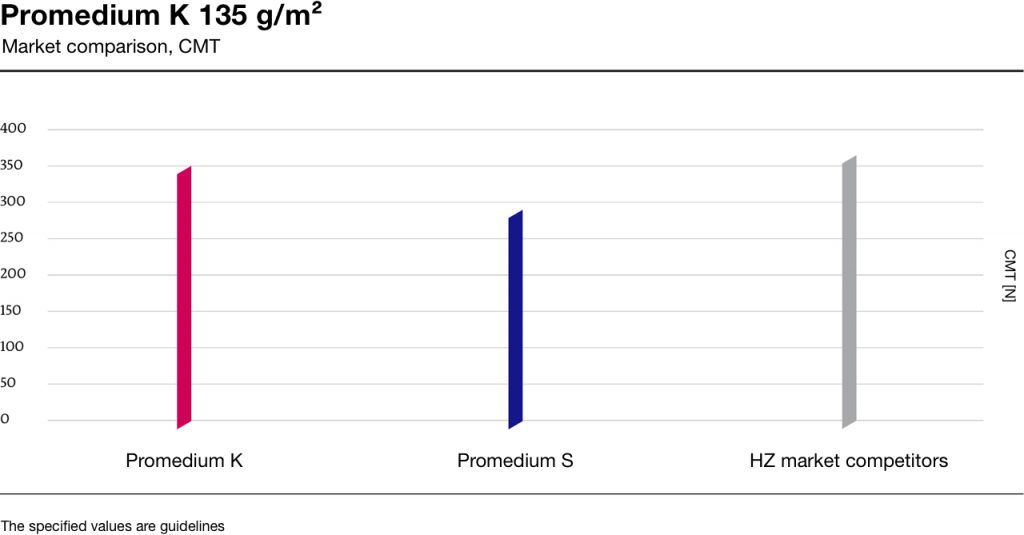

High-performance fluting optimised in CMT and SCT.

Use

Grammage

Wet strength

Approval

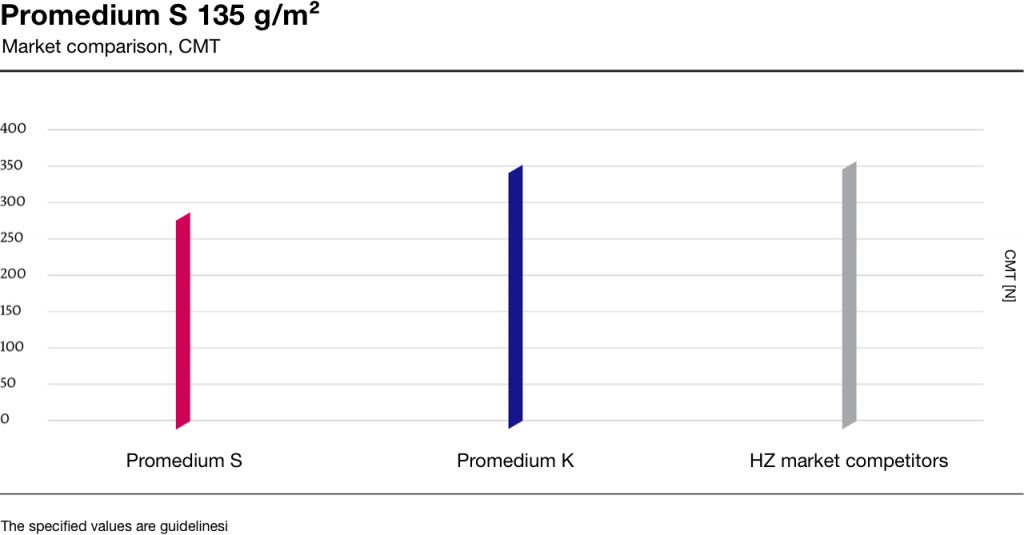

The high-quality semi-chemical pulp substitute for higher CMT values.

Use

Grammage

Wet Strength

Approval

The “green” basis for a new corrugated board generation.

Special properties:

Use

Approval

The “green” basis for a new corrugated board generation.

Special properties:

Use

Approval

| Working width | 9,20 m |

| Annual production | 750 Tto Containerboard |

| Daily production | 2.430 t LE |

| Specific production rate | > 11 t/h/m |

| Grammage range | 90 - 130 gsm |

| Design speed | 1.700 m/min |

| Operating speed | 1.600 m/min |

| Commissioning | 2nd half of 2020 |

| Size of plot | 450,000 m² |

| Total investment | 375 million Euro |

We have put together for you the answers to the most frequently asked questions about a wide range of different topics relating to paper production and safe use with foodstuffs. If your concern or question has not been addressed, we ask you to get in touch with us.

Beyond that, the following recovered paper types are not used for the production of containerboard at Propapier:

REACH Regulation (EC) No. 1907/2006

Pursuant to the REACH Regulation, the qualities produced by Progroup Paper are “products” which are not subject to the registration requirement.

As a so-called “downstream user”, our plants are not subject to the REACH registration requirement either. However, we can assure you that, at present and in the future, we will only use raw materials, additives and finishing substances which are registered pursuant to the REACH Regulation.

Biocides & preserving agents

The biocides & preserving agents used in our production are in compliance with the current Regulation (EU) 528/2012 and are used to treat the water loop. There is no direct application in the final product. The use of Methylisothiazolinone can occur, but there are no residues detectable in the products (detection limit 0.5

PM1

EnMS DIN EN ISO 50001

FSC® certification (FSC-C106840) according to standard FSC-STD-40-004 version 2-1 and FSC-STD-40-007 version 2-0.

PM2

UMS pursuant to Regulation (EC) No. 1221/2009 (EMAS III Regulation)

FSC® certification (FSC-C106924) according to standard FSC-STD-40-004 version 2-1 and FSC-STD-40-007 version 2-0.

The grades produced by Progroup Paper – Promedium, Proliner, Promedium S, Promedium K, Proliner K and Prokraft – are safe to be used as food packaging. They may be in direct contact with dry, non-greasy food. Dry, non-greasy foods with a large surface area (e.g.: rice, pasta, semolina) may be packaged with the additional use of suitable intermediate packaging. The food safety of the paper grades is regularly checked and updated. The declaration of no objection is in compliance with:

At eleven sites in Europe, Progroup produces high-quality corrugated sheetboard. The product range includes a wide selection of profiles of single-wall, double-wall or triple-wall corrugated board. The sheets that are produced on high-tech machines are 100% recyclable.

Progroup offers high-performance containerboard and corrugated board in the form of Next Fibre®, Next Board®. Progroup develops products that are environmentally friendly and conserve resources by making investments in new papers, new corrugated board designs and new technologies.